LÖMI Debinding Systems for Metal and Ceramic Injection Moulding. LÖMI plants can process numerous feedstocks as they extract the binder components with organic solvents or with water. All plants use our advanced clean technology in a closed system and feature a PLC automated process with real-time parameter visualisation via touch panel.

PIM Debinding Systems (MIM CIM)

APPLICATION

LÖMI Debinding Systems for Metal and Ceramic Injection Moulding. LÖMI plants can process numerous feedstocks as they extract the binder components with organic solvents or with water. All plants use our advanced clean technology in a closed system and feature a PLC automated process with real-time parameter visualisation via touch panel.

Advantages

- Cost-saving

- Compact design

- Process-reliable and easy to handle – through advanced clean technology

- Fully customisable – by means of Programmable Logic Control PLC

- Environment-friendly – through a closed system

Powder injection molding is a process of manufacturing geometrically complex parts from materials that are demanding with regard to machinability, like carbide or ceramics / keramics. Powder injection moulding is particularly suited for small parts with medium and large lot sizes. The process is characterised by its high rate of yield with regard to the raw material.

Powder Injection Moulding consists of three process steps:

- At first, parts close to their final contours are shaped on standard injection moulding machines – the so-called green parts.

- The following Debinding – the removal of the binder components that were necessary for the shaping process – is realised through extraction by organic solvent or water. The moulded part turns into the so-called brown part.

- The last process step consists of Sintering under high temperatures. As a result, we obtain the metal or ceramics part that shows its final geometrical and material properties and which is ready to use.

EDA Model Series

For small numbers of injection moulded parts, the EDA model series combine debinding, vacuum drying and solvent recovery in one single unit.

EBA / MDA Model Series

For medium and large numbers of injection moulded parts: EBA model series with a parallelly operated solvent recovery system of MDA model series.

EBA-E Model Series

Debinding systems with special process chamber geometry and adapted loading trays, compatible with the sinter furnace series MIM 3000 of Elnik Systems.

EBA-W Model Series

Debinding systems with water extraction process for special feedstocks. They feature a horizontal vessel in a compact housing.

Manufacturing Process AM

Debinding systems for the manufacturing process Industrial 3D Printing / Additive Manufacturing AM.

EDA Model Series

Application Range

- For small numbers of parts

- 3 in 1:

- Debinding

- Parts drying

- Solvent recovery

- 25 to 135 l batch loading volume

Downloads & more

Solvent Debinding EDA model series for small numbers of parts:

Debinding Tabletop Unit EDA-30 for research, prototyping and small batch production:

EBA / MDA Model Series

Application Range

- For medium and large numbers of parts

- 3 in 1:

- Debinding

- Parts drying

- Solvent recovery (via connected solvent reprocessing system of MDA model series)

- 25 to 1.200 l batch loading volume

Downloads & more

Solvent Debinding EBA model series for medium and large numbers of parts:

Solvent Reprocessing MDA model series for binder systems and other liquid residues:

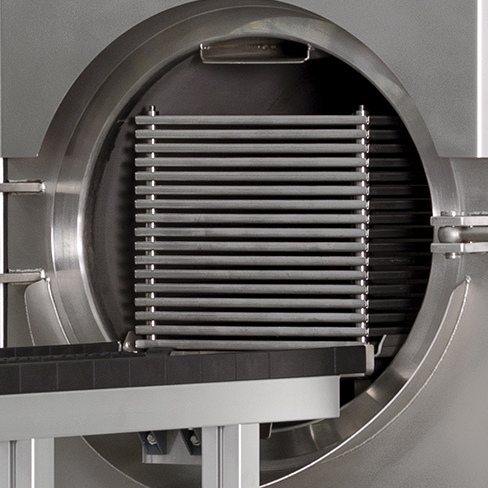

EBA-E Model Series

Application Range

- Loading shelves compatible with sintering furnace series MIM 3000 by Elnik Systems

- 3 in 1:

- Debinding

- Parts drying

- Solvent recovery (via connected solvent reprocessing system of MDA model series)

- 30 to 120 l batch loading volume

Downloads & more

Solvent Debinding EBA-E model series for use with sintering furnaces of Elnik Systems:

EBA-W Model Series

Application Range

- Debinding systems with water extraction process for special feedstocks

- For small numbers of parts

- 2 in 1:

- Debinding

- Parts drying

- 25 to 135 l batch loading volume

Downloads & more

Water Debinding EBA-W model series for small numbers of parts:

FAQ

One advantage is that MIM/CIM parts producers can freely choose their feedstock manufacturer, as numerous different feedstocks can be debound with the solvent debinding process. This allows PIM parts manufacturers to test different feedstocks or to choose a new feedstock manufacturer without having to invest in a new debinding system.

A further advantage is that solvent debinding systems are very durable, as the process exposes them to little wear and tear. Furthermore, very compact plant dimensions are possible.

Part of every LÖMI solvent debinding system is a solvent recovery unit, which continuously provides fresh debinding medium. The recovery rate is up to 99 percent, so that our debinding plants are very cost-saving and environmentally friendly.

Yes, LÖMI offers a wide range of charging trays. By changing the spacer bolts of different lengths between the trays, parts with different heights can be debound in one batch if required. Furthermore, we are happy to manufacture specially adapted charging trays.

Auxiliary Equipment PIM Debinding

- Loading carts

- Perforated plate & wire mesh trays

- Rack systems adapted to sintering furnaces of various manufacturers

- Cleaning tools

- Collecting trays

- Tanks – optionally with:

- Heating

- Cooling

- Stirring unit

- Integration in system frame

- Cooling systems